Cement Sector

February 24, 2023 2023-03-02 6:33Cement Sector

Cement Sector

India is the second largest producer of cement in the world. The recent boom in infrastructure and the housing market has paved way for a growth trajectory in the cement industry. A flurry of activities in infrastructure projects – highways roads, bridges, ports and houses – has only added to the increased demand.

The progress of the nation depends on cement. The progress of cement industry depends on process behind the manufacturing. Every cement manufacturing industry needs a robust and reliable material handling system. Bevcon Wayors has been the pioneer in providing RMHS (Ram material handling system); Clinker conveying and other equipment to all major cement manufacturers.

We have been responsive to client requirements with respect to delivery and project commissioning and we have received many repeat orders in cement sector from leading organizations like UltraTech Cement, Madras Cement, ACC, Shree Cements etc. We also provide turnkey solution to the material handling requirements of the infrastructure industry including supply of crushing, screening, conveying, stacking, reclaiming, etc.

Apart from standard conventional material handling equipment’s. Bevcon Wayors specialized in new generation – special / innovative conveying systems & material handling equipment like:

• 90° steep angle cleated belt conveyors.

• Sandwich type high angle belt conveyors.

• Over land / long distance / cross country conveyors & pipe conveyors.

• Cost-effective pollution free pneumatic conveying systems.

• Special flip flow screens for high moisture material screening applications.

• High efficient sugar graders.

• Stockyard equipment like radial & liner stackers & reclaimers etc.

2900 TPH Lime Handling System

| SYSTEM | Overland Pipe Conveyor for conveying Limestone from Mine to Process Plant |

| CLIENT | Shree Cement |

| LOCATION | Khapradih, Raipur, CG |

1.5 MTPA Split Grinding Unit

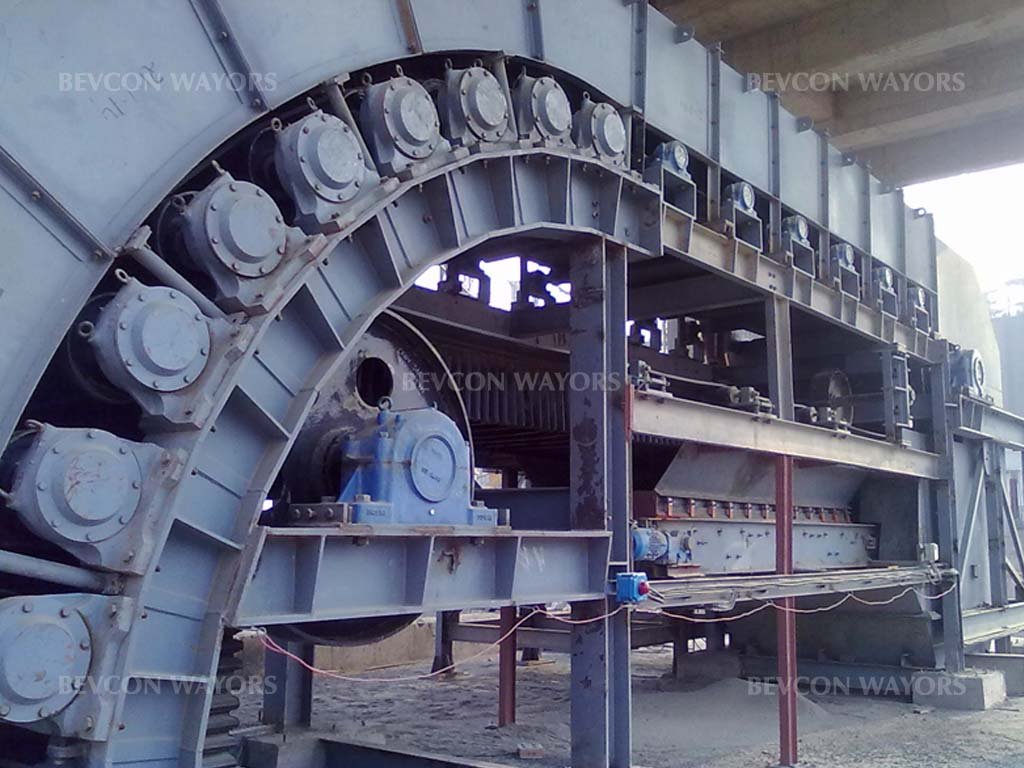

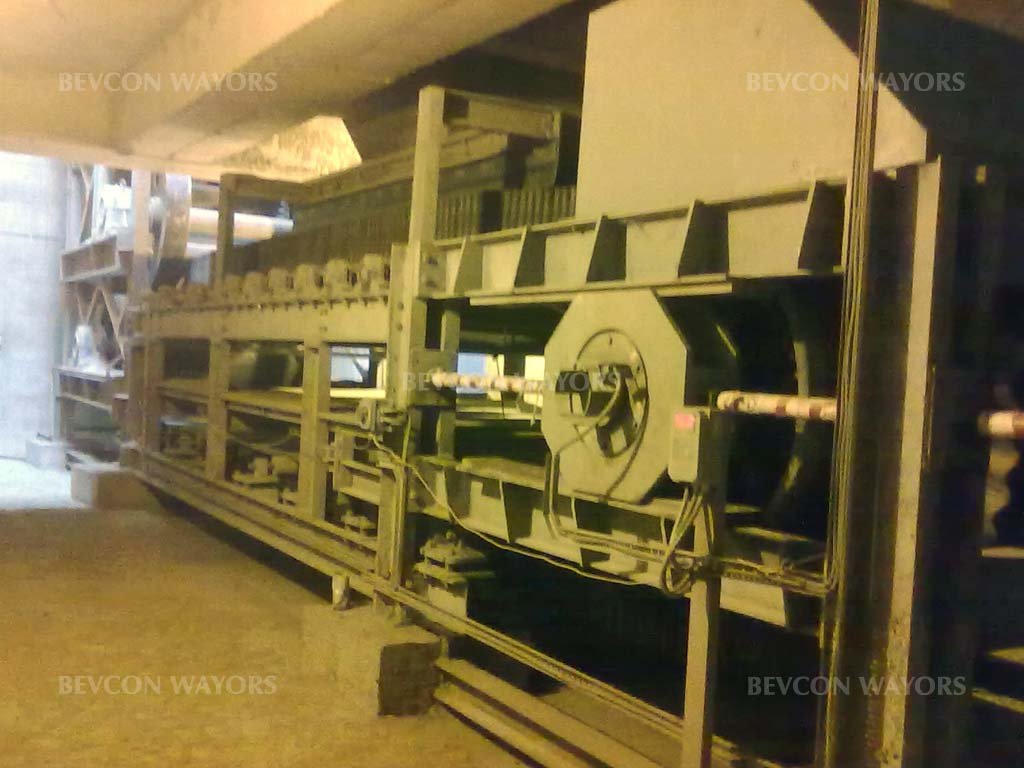

| SYSTEM | First-of-its-kind in Indian Cement Industry – Steep Angle 90 deg. Sidewall Cleated Belt Conveyor Clinker Handling System of 1500 TPH from Wagon Unloading area to Storage Silo |

| CLIENT | JK Cement Ltd. |

| LOCATION | Jhajjar, Haryana |

1.5 MTPA Brown field Cement Plant, 10MW Waste Heat Recovery Plant and 25MW Captive Power Plant

| SYSTEM | Raw Material Handling System (Limestone, Additives, Raw Coal, Clinker & Fly Ash) |

| CLIENT | JK Cement Ltd. |

| LOCATION | Mangrol |

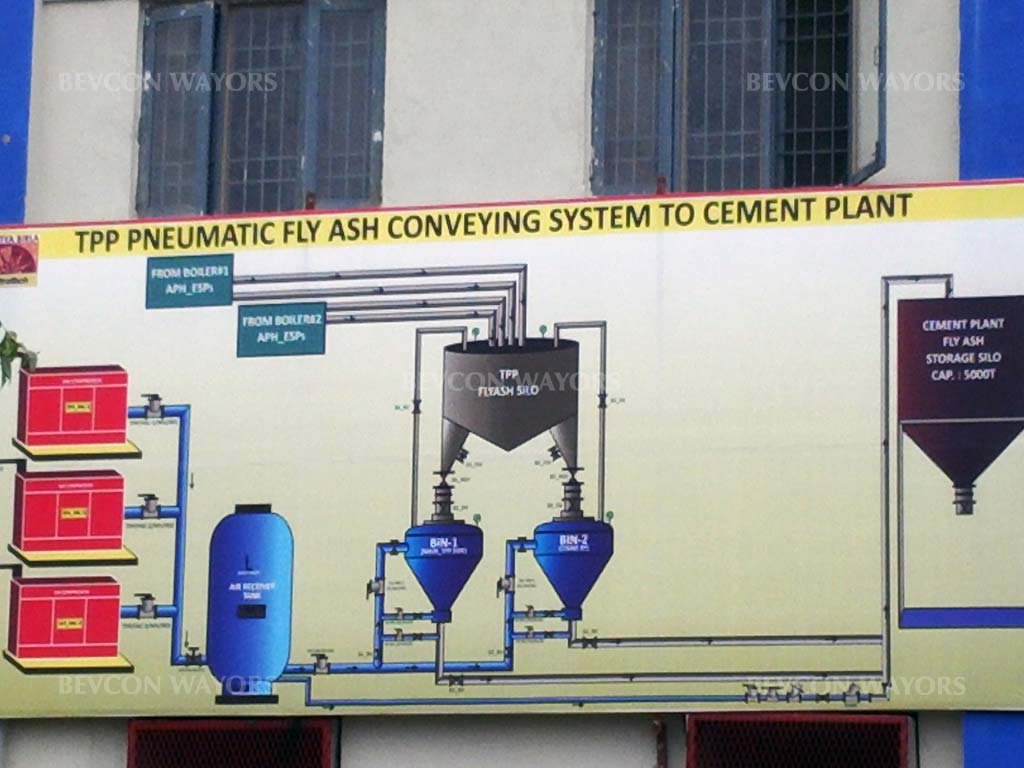

2 x 33MW Power Plant

| SYSTEM | Dense Phase Pneumatic Conveying for conveying Fly Ash over 650Meter distance from their Power Plant Ash Silo to Cement Mill Silo |

| CLIENT | UltraTech Cement Ltd. |

| LOCATION | Kotputli, Rajasthan |

1.5 Million MTPA (Green-field projects)

| SYSTEM | Fuel Handling System (Imported Coal / Limestone / Bed material ) |

| CLIENT | Dangote Cement |

| LOCATION | Zambia, Africa |

2.2 Million MTPA

| SYSTEM | Raw Material Handling System (Clinker, Uncrushed Gypsum & Additives) |

| CLIENT | Reliance Cement |

| LOCATION | KUNDANGUNJ, UP |

1 x 40 MW Captive Power Plant

| SYSTEM | 150 TPH Coal & 50 TPH Lime Material Handling System |

| CLIENT | Wonder Cement |

| LOCATION | Chittorgarh, Rajasthan |