Mechanical Ash Handling System

February 24, 2023 2023-03-02 7:21Mechanical Ash Handling System

Mechanical Ash Handling System

In Thermal Power Plant’s coal is generally used as fuel and hence the ash is produced as the byproduct of Combustion. Ash generated in power plant is about 30- 40% of total coal consumption and hence the system is required to handle Ash for its proper utilization or disposal.

A Mechanical Ash Handling System is often the best choice for fluidized bed ash where headroom is restricted under the boiler. The Mechanical Ash Handling System handles the ash by Bottom Ash Handling System, Fly Ash Handling System, Ash disposal system up to the Ash disposal area and water recovery system from ash pond and Bottom ash overflow.

Types of Mechanical Ash Handling System

– Bottom Ash Handling System

– Fly Ash Handling System

Bottom Ash Handling System

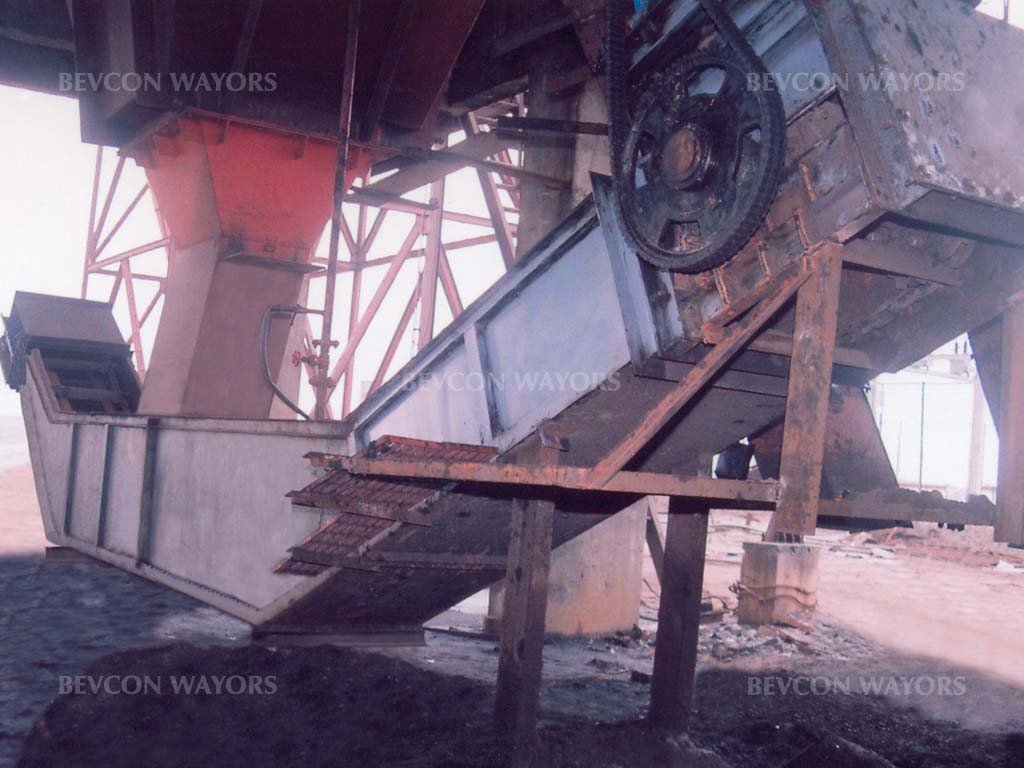

Bottom ash is continually collected, cooled and dewatered with a submerged chain conveyor. Ash falls constantly from the boiler through a discharge hopper into a water filled chamber upper trough that quenches and cools the ash. Dual-strand chains and flights move the ash along the horizontal trough and up a dewatering ramp for disposal. The inclined section allows excess water to be drained from the ash material. At the top of the ramp, the ash falls through a discharge chute into trucks for final disposal. Bottom ash conveyors are available in varying sizes and capacities ranging from 5TPH to over 50TPH

Fly Ash Handling System

Fly ash is considered to be collected in ESP Hoppers. Fly ash from electrostatic precipitators or fabric bag filters located at the outlet of the furnace and before the induced draft fan is extracted by Vacuum Pumps. Totally enclosed, dust-tight, air-tight drag chain conveyors receive fly ash through seal valve or mate directly to fly ash hoppers. Available in single-strand and double strand chain. Can convey material horizontal or inclined up to 35Deg over 50meters in length.

Fly Ash Utilization includes:

– Concrete production, as a substitute material for Portland cement and sand

– Embankments and other structural fills (usually for road construction) Waste stabilization and solidification.

– Cement clinkers production – (as a substitute material for clay)

– Mine reclamation

– Stabilization of soft soils

– As Aggregate substitute material (e.g. for brick production)

– Mineral filler in asphaltic concrete

– Agricultural uses: soil amendment, fertilizer, cattle feeders, soil stabilization in stock feed yards, and agricultural stakes

– Loose application on rivers to melt ice

– Loose application on roads and parking lots for ice control

– Other applications include cosmetics, toothpaste, kitchen counter tops, floor and ceiling tiles, bowling balls, etc